BROACH

Utilizing decades of expertise and experience, we deliver solutions tailored to customer needs.

We manufacture and sell surface broaches, internal broaches, and other tools for processing automobile components such as engines, steering, brakes, and suspensions, drawing on years of experience.

Through cutting, heat treatment, grinding, and surface treatment techniques for various materials, we provide tailored solutions that cover everything from design and development to manufacturing, quality, and delivery.

We provide comprehensive support to improve product quality, reduce costs, and increase efficiency in customers’ manufacturing processes.

Leveraging our broach manufacturing expertise, we also deliver high-precision, high-quality ejector pins for die-casting molds.

Examples of Automotive Component Processing

1Engine Component Processing

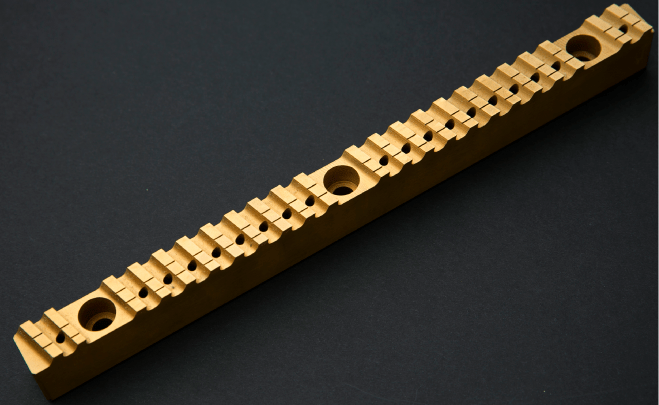

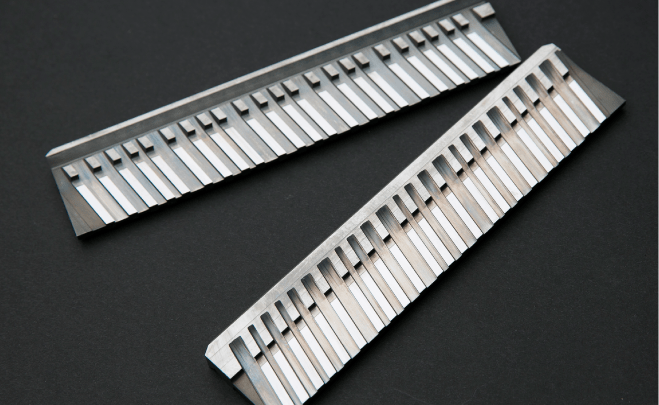

Surface Broach

For flat machining of engine parts, end-face machining of bearing components, and general surface cutting.

H18×W22×D320mm

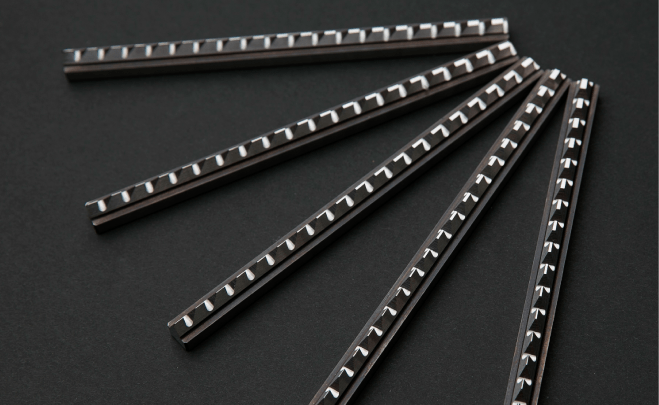

Special Surface Broach

For V-groove machining of engine parts and irregular flat surfaces.

H10×W13×D180mm

2Transmission Component Processing

Internal Broach

For machining transmissions, axle shafts, clutches, handle yokes, joint yokes, and other internal diameters.

φ6×500mm/φ150×1800mm

3Steering Component

Processing

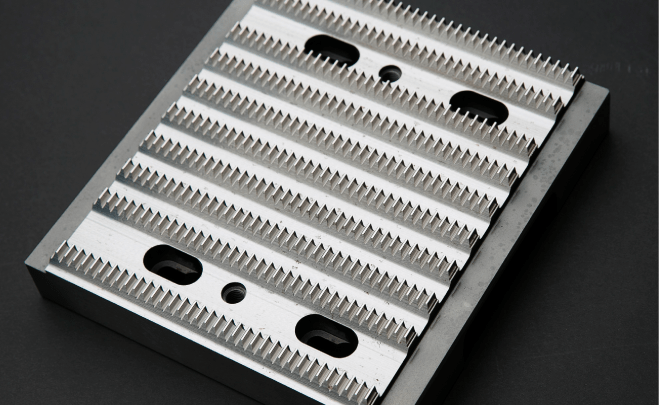

Rack Surface Broach

For steering rack machining.

H220×W×D280mm

4Suspension/Undercarriage

Component Processing

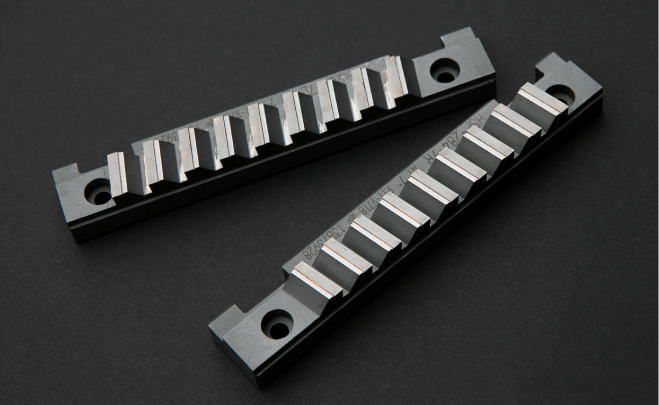

Carbide-Tipped Broach

For machining bearing caps and mountain disc brakes.

H18×W22×D180mm

5Drivetrain Component Processing

Special Double-Chamfer Broach

For square-hole machining of constant-velocity joint internal components in drive shafts.

H20×W24×D800mm

Other Product Processing Examples

Solid Carbide Broach

Precision finishing tool for air conditioner outdoor units and refrigerator compressors.

H9×W47×D180mm

Ejector Pins

Incorporated into molds for producing aluminum die-cast products.